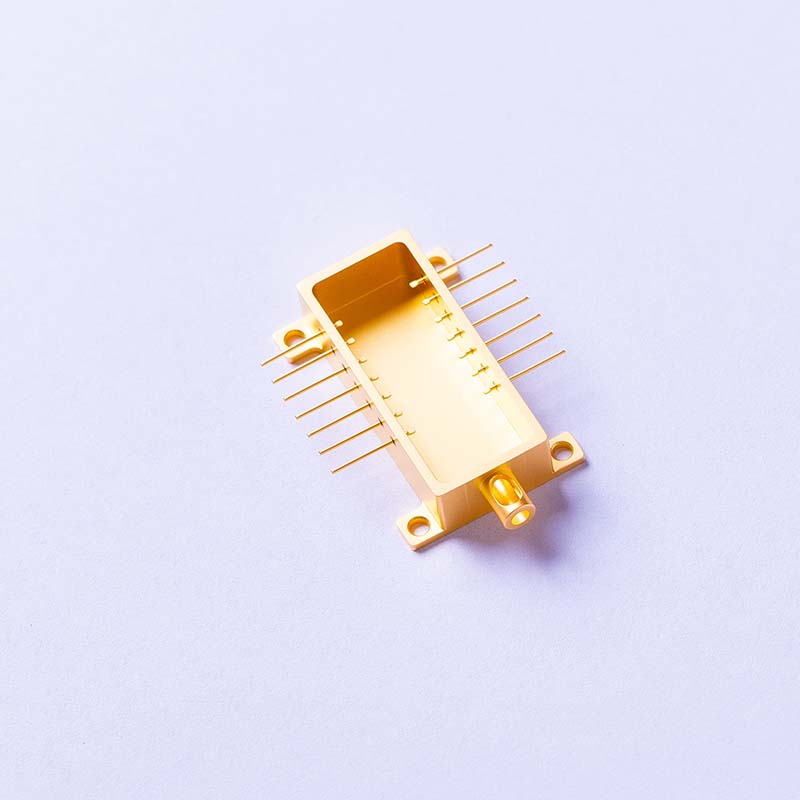

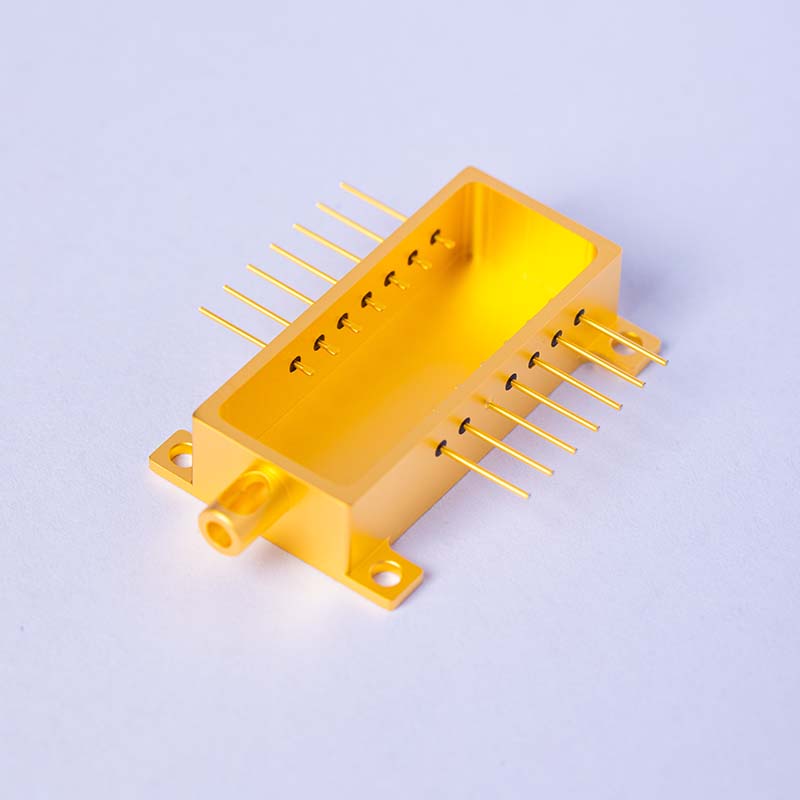

MDFO6866-p54 Information

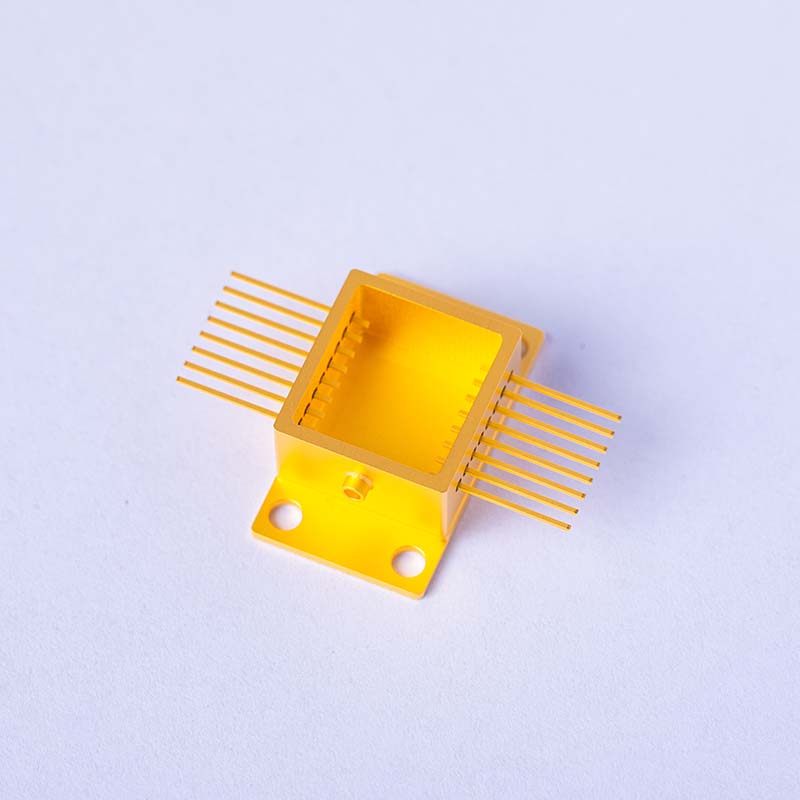

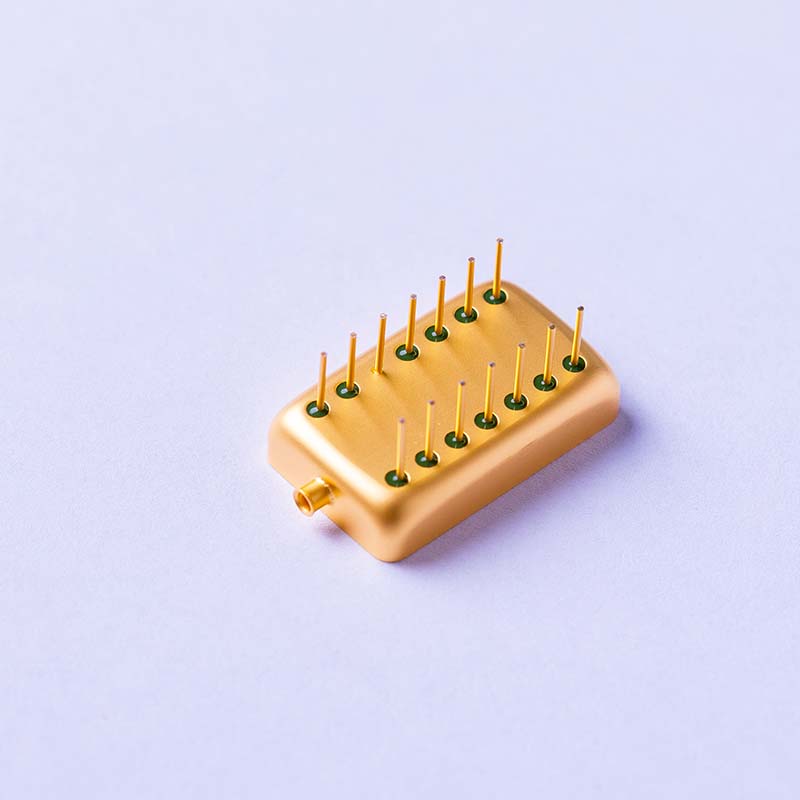

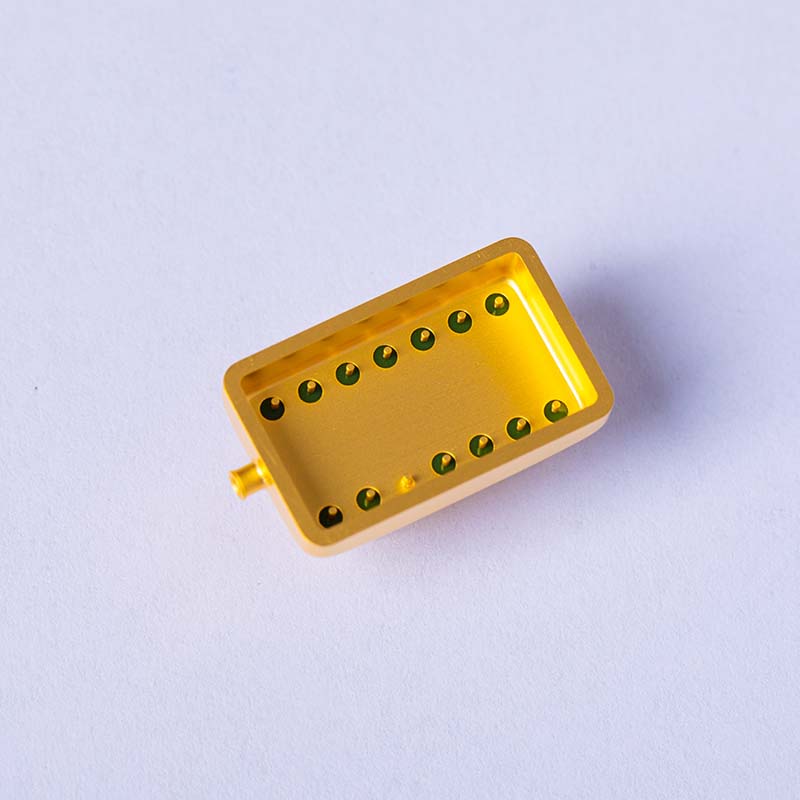

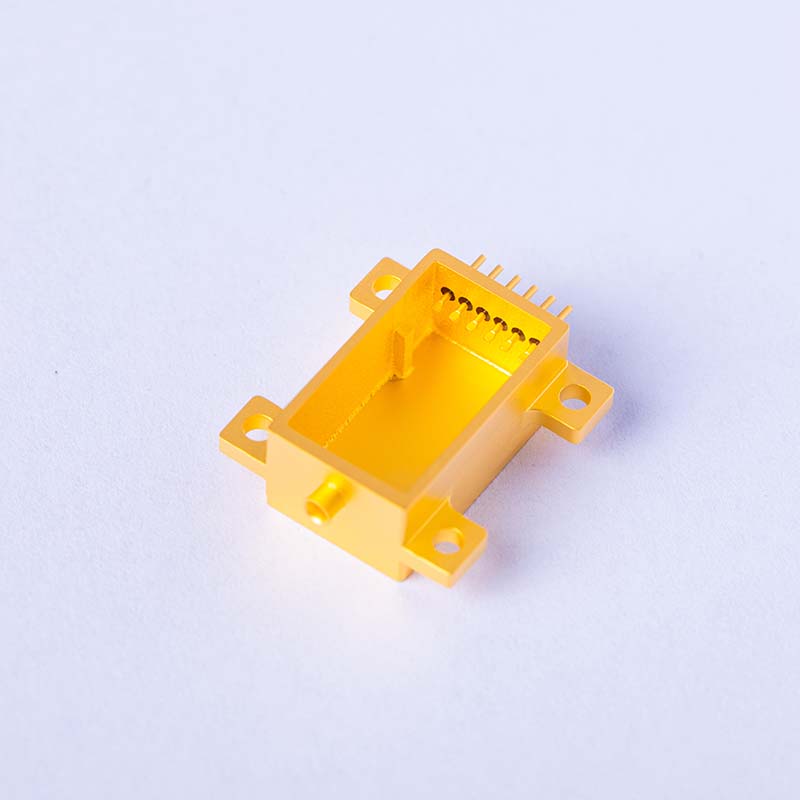

The MDFO6866-p54 is a cutting-edge product designed for opto electronic packaging applications. This advanced solution incorporates a glass to metal sealing process, ensuring robust and reliable performance. The package features 54 leads made from Kovar, a renowned material known for its exceptional thermal and mechanical properties.

With a fiber optic channel and assembly eyelids, the MDFO6866-p54 offers seamless integration and enhanced versatility. The product is finished with a high-quality Au coating, further enhancing its durability and conductivity. Engineered with precision and expertise, this opto electronic packaging solution guarantees optimal functionality and long-lasting performance.

Main Applications

These products are characterized by their good sealing qualities and excellent heat dissipation. The following are some main applications of this excellent laser butterfly package:

Optical transmitters, optical detectors, optical modulators, amplifiers, and high-power lasers are widely used in automotive electronics, optical communications, medical equipment, and public safety.

| MDFO6866-p54 |

| | Housing | Tube | Leads | Insulator | Solder ring |

| Materials | 4J29 | DM308 | HLAgCu28 |

| Plating | Ni:1.3~8.9μm, Au: ≥1μm | Ni:1.3~8.9μm, Au: ≥1.3μm | |

| Dimensions | L:68mm,W:66mm,H:12.75mm |

| Insulation resistance | ≥1× 1010 Ω (500V DC) |

| Hermeticity | ≤ 1 x 10-3 Pa * cm3 /s |

| Note | Unspecified tolerances are ±0.2mm |

With over two decades of experience helping clients move from prototype to commercialization, Hermetix customized engineering service offers immense value at the R&D stage. From material selection to pin configuration to sealing techniques, our engineers can provide various solutions to help you overcome the technical obstacles our clients face in the early phases of designing a new product. We can work from your drawings or ours while pinpointing ways to lower costs and improve functionality.

Customization Process

Hermetix Hermetix Optoelectronic Packaging process includes the following steps

Step 1: Understanding Client Needs

Hermetix engineers collaborate with clients to identify the project’s technical requirements and end-use.

Step 2: Design the Optoelectronic Packaging

Hermetix engineers draft technical drawings focusing on workability from the productions’ point of view and end-user, e.g., bonding and sealing requirements.

Step 3: Monitoring Production Progress

Hermetix keeps track of suppliers’ manufacturing processes, including updating clients on progress and ensuring lead times.

Step 4: Inspection + Shipping

Once products are finished, Hermetix will verify product compliance and ship.

Step 5: After-Sales Services

Hermetix ISO 9001 – Certified Quality Assurance team follows standardized procedures to address and remedy any quality issues immediately.